- Niky Baker

- Jan 19, 2022

- 2 min read

Updated: Jan 20, 2022

The answer to that question in short is obviously to save lives and property, and in recent times, fire protection has hit the headlines with all of the media coverage of the Grenfell disaster. When people asked what I did for a living and I explained that we manufacture and supply passive fire protection products, they looked at me a bit blank, not knowing how to carry on the conversation, but now people seem to understand more about what we do.

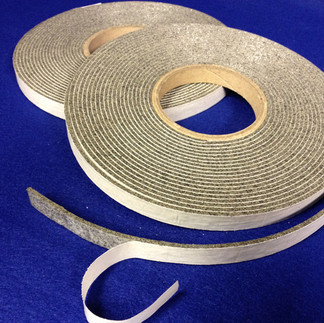

Passive fire protection is everywhere, silently doing its job, hoping that it will never have to come into use. From the intumescent strips hidden within doors and the collars around pipes that carry services and wires from one level of a building to another, to the fact that humble plasterboard is 30 minutes fire rated so that there is some level of protection.

I guess most people who go in and out of public buildings and workplaces if asked would expect that there would be fire extinguishers, sprinkler systems alarms, and smoke detectors all around them to keep them safe, but not as many would give thought to the passive fire protection that had been cleverly designed into a modern building or retrofitted into a historic building.

It’s there in your homes, the fire retardant materials used in your mattresses and sofas, your loft insulation is most likely to made from glass fibers and therefore is non-combustible and all three-story buildings must have fire doors installed by law.

Passive fire protection is used in all public transport, with testing methods unique to where the protection will be placed, there are many testing houses or centers with slightly different testing methods and standards that are recognized in different countries, which makes the subject a little more confusing for someone trying to decide which is the best materials to use, but whenever you are fitting passive fire protection, the most important thing is to refer to what has been specified by an architect or a fire officer.

When potential customers contact us, we always make sure that they are confident that they are installing the correct material for the application. If they’re unsure or need advice we’re very happy to help or provide them with the information required to install the correct products and in over 30 years we’ve helped many people, after all, the reason that passive fire protection is so important is that it saves lives.